|

QUANG VIET

HOME

»

PRODUCT

»

PU

Foaming Resins

2-components PU Foaming Resins

INTRODUCTION:

|

The product applications of 2-component PU

Foaming Resins are quite

extensive.

From insulation materials, shoes

materials,

bionic materials (e.g. PU artificial flowers), furniture,

water-proof materials, to various one-piece PU

objects (e.g.

wood-like bath tub,

PU Integral-skin product) have excellent performances. According to

physical properties,

PU foaming resins

mainly divided into:

Rigid Foam, Semi-rigid foam, Flexible foam,

HR foam, LR foam, and Integral Skin foam, etc. |

|

CATEGORY:

1. RIGID:

After deformed by external force, end product can't restore original shape.

2. FLEXIBLE:

After deformed by external force,

end product

immediately restore original

shape,

resilience is lower.

3. HIGH RESILIENCE:

After deformed by external force,

end product

immediately restore

original

shape,

resilience is higher.

4.

SEMI RIGID:

After deformed by external force,

end product partly

restore original shape.

5. LOW RESILIENCE:

After deformed by external force,

end product

slowly restore original shape.

6. INTEGRALSKIN: Surface of end foam product forms thick

skin.

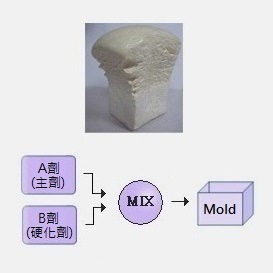

HOW TO HANDLE:

Suitably mix 2 components of foaming resin (A component

& B component) by suggested weight ratio then put into

the mold. Waiting for it swells and cures to get end PU

foam object. PU foaming method mainly

divided into 2 kinds, free

foaming and in-mold foaming. Making color products,

colorants should be add into A component first and

adequately mix, then add B component into.

PACKAGES:

|